R&D team

The spirit

of Huayang people

learning

Endeavor

Collaborating

Responsibility

Having a vibrant design team,

Using internationally advanced CAD, CAN, and CAE software to assist in mold design,

Enable products to predict and solve problems at the earliest stages of development.

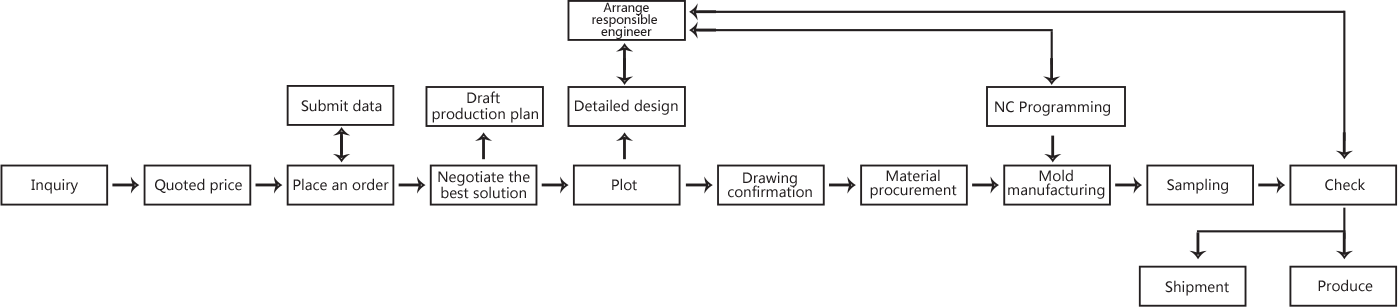

manufacturing process

Within 3 days of receiving inquiry

Start the project after the advance payment is in place

Plot after 3-7 days

Customer confirmation

Engineers are responsible for product information and quality control

Weekly schedule tracking

Test the mold and issue a detailed report

Based on customer data detection

Completion

inspection items

Raw Material Test

MORE

Raw Material

Test

Mold inspection

Material certificate

Mold material inspection report

Hardness, size, and other testing reports

Standard parts inspection

Hardness, size, and other testing reports

Use specification sheet and instructions

Mold base inspection

Standard mold base inspection report

Electrode detection

Electrode detection report

process inspection

MORE

Process

Inspection

Inspection of machining processes (machining centers, electric sparks, etc.)

Process inspection report

Heat treatment testing

Modulation, stress relief, nitriding, quenching, carbonitriding

Assembly process inspection

Mold accuracy testing report

Mold testing

Trial mold inspection report

Demolding inspection

Demolding inspection report

Product Test

MORE

Product

Test

FAI full size inspection

Three coordinate detection center

Testing of test specimens

Delivery Inspecion

MORE

Delivery

Inspecion

Mold inspection (appearance, spare parts, instructions, etc.)

Mold Shipping Checklist

Packaging inspection (material, size, fit, etc. of packaging)

Packaging Review Report